Dowco’s Lean Initiatives

Dowco has instituted continuous improvement practices into all levels of our organization. This means that formal work instructions and procedures have been developed within all areas of the company to promote standardization and consistency of operations which promotes error free work.

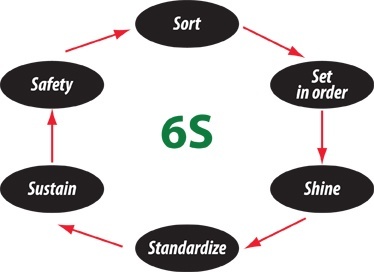

At Dowco, 6S is a tool used throughout the organization to sustain Dowco’s lean culture and engage all employees in continuous improvement. 6S prevents waste and concentrates on higher efficiencies, less stress, fewer accidents, higher levels of quality and fewer breakdowns.

Lean initiatives allow Dowco to reduce customer inventory levels and deliver quality products on time based on customer demand. This helps increase the velocity of product through customer facilities while reducing the overall costs of doing business together.

Our Quality Assurance department has been formalized and empowered to develop and implement quality systems necessary to ensure the highest level of customer satisfaction possible. An extensive collection of metrics has been established and communicated to employees to ensure an understanding of our current level of performance and to continually identify opportunities for improvement.

The Pillars of 6S:

Safety

Respect the workplace and employees to create a safe and productive work environment

Set in Order

Identify the best location for remaining items, relocate out of place items and set inventory limits

Shine

Reduce Paperwork

Sort

Reduce Clutter and Out dated items

Standardize

Create rules for maintaining the first 4s and use visual controls reducing errors

Sustain

Ensure adherence to 6S standards through communication, training and self discipline. Improve time management.

LOOKING FOR A STRATEGIC PARTNER? CONTACT US TO GET STARTED!

MANUFACTURING

LOCATIONS

Lebanon, MO

Ft. Wayne, IN

Shanghai, China